Machine Vision: Xenon Flash Strobe

PHOXENE, WORLDWIDE MANUFACTURER OF FLASH STROBES

For over 25 years, Phoxene has acquired know-how in the technical design, manufacture and sale of flash solutions for various industrial applications, including Machine Vision. Phoxene has delivered thousands of flash devices to system integrators worldwide.

MACHINE VISION AND LIGHT SOURCES

Why does Machine Vision take advantage of a light source?

Machine vision involves photon capture by a camera. In its most derivative form, machine vision is characterizing light contrasts patterns from an object. More photons means more details on a resulting image. Nevertheless, any light other than the vision-specific lighting may produce adverse effects on image quality, by creating shadows or reflections. The presence of ambient light input can have a tremendous impact on the quality and consistency of inspections, particularly when using a multispectral source such as white light.

Lighting sources for machine vision

The lighting sources now commonly used in machine vision are fluorescent, quartz halogen, LED, metal halide (mercury), and xenon.

Fluorescent, quartz halogen, and LED are the most widely used lighting types in machine vision, particularly for inspection stations dedicated to small- to medium-sized objects. Xenon is more typically used in applications involving large objects or in areas requiring a very bright source. A xenon source is useful for applications requiring a very bright strobe light.

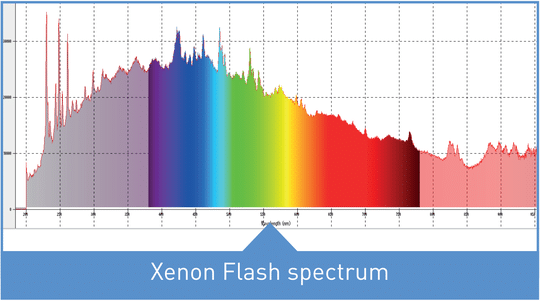

Xenon Flash spectrum for Machine Vision

Colorimetry, quality control, inspection and pattern matching all require a precise and large spectrum.

Color can be measured by instrumental and machine vision methods. Colorimeters and spectrophotometers can quantify color very precisely, but as averaged values on a sample: a problem may arise when the sample has non-homogenous colors. Conversely, machine vision may be less precise than a spectrophotometer in terms of color identification, but is able to detect color spots or color variations on a single sample.

The spectrum produced by xenon flash sources is rich in visible and IR emission. UV is usually filtered-out by the glass wall itself, but can be enhanced for some applications.

In the visible band, the Xenon Flash spectrum is close to that of a blackbody radiator at 6000K.

Additionally, this spectrum is very stable and repeatable. This allows color measurements by machine vision methods.

HIGH POWER LEVEL FOR MACHINE VISION

Advantage goes to Xenon Flash

All too often, when setting up a system, integrators spend too much time looking at the application or the processing of the information. They should focus more on lighting. Vision has always been about lighting and image capture. Proper lighting is crucial for guidance systems to function properly and consistently. So is it for identification or gauging.

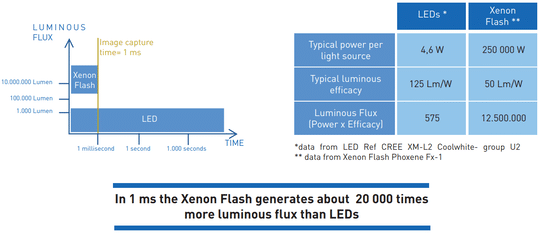

Ambient light frequently impedes Machine Vision capabilities. A high power light source able to surpass ambient light is a serious asset to obtain images with reproducible quality. This is particularly true for outdoors applications, where a xenon flash can surpass sunlight at a distance of multiple meters.

As an additional benefit, a very high power light source will also allow image capture at longer distances, or improve the depth of field and enable computational imaging.

The high power level of xenon flash strobes is particularly obvious in comparison with LED sources: see table below.

Short duration pulses to freeze motion

Some Machine Vision applications can take advantage of the short pulses of light produced by xenon flash illuminators, for example to freeze images of fast-moving objects on a high-speed production line. Thus, the combination of very high power and short duration allows image captures otherwise impossible.

One of the biggest challenges with high-speed imaging is the illumination. With high speed, very short exposure times and very intense illumination are needed. In such cases a xenon flash can bring the necessary illumination intensity.

The exposure length may be longer than the light pulse, but since a very short pulse is used, the effective exposure length achieved is essentially as short as the light pulse itself — thus ‘freezing time’ in a very simple manner for the user.

Our flash strobe solutions for Machine Vision

Your application requires high light stability and good color rendering ? short pulse of intense light emission ?

Sx-1 and Sx-3 are two models of the Phoxene range specifically designed for Machine Vision. Phoxene customers use them for on-line quality control, precision farming and outdoor imaging, industrial test bench…

Go through the presentation of the two products : Phoxene Xenon Flash for Machine Vision or visit our product section